-

Новости

- ИССЛЕДОВАТЬ

-

Страницы

-

Группы

-

Мероприятия

-

Статьи пользователей

-

Offers

-

Jobs

-

Courses

Safety and Compliance: Transparent Film Wrapping in the Pharmaceutical Industry

For many products, particularly those in the food and beverage industry, an attractive and well-packaged item can increase consumer appeal and encourage sales. The ability to clearly see the product inside the package adds value, making the product more appealing to potential buyers.

The use of transparent film wrapping also allows for greater branding opportunities. The film can be easily customized with printed logos, product information, or promotional messages, making it an effective tool for marketing. While the transparency of the film allows consumers to see the product, it also offers space for branding and informational prints without detracting from the product’s visual appeal.

For example, companies can print nutritional information, ingredients, or company logos directly onto the film, reinforcing their brand identity while maintaining a professional, clean presentation. This flexibility is especially valuable for businesses looking to create unique packaging that differentiates their product in a competitive marketplace.

One of the most significant advantages of automatic transparent film wrapping machine is their speed and efficiency. These machines can wrap a large number of products in a short amount of time, making them ideal for industries with high production demands. Compared to manual wrapping methods, which can be slow and labor-intensive, automatic machines are far more efficient, reducing bottlenecks in production lines.

The increased speed of automatic wrapping machines directly translates into higher productivity, allowing businesses to meet consumer demand more effectively. In industries like food packaging, where freshness and shelf life are crucial, fast and efficient packaging is essential to maintaining product quality and meeting delivery deadlines.

Another advantage of using automatic transparent film wrapping machines is the consistency and high quality of the packaging. Manual wrapping often results in variations in film tension, folding, and sealing, which can lead to inconsistent packaging that looks unprofessional or leaves the product inadequately sealed. Automatic machines, however, operate with precise control over the wrapping process, ensuring that each product is wrapped uniformly and securely.

This consistent packaging is crucial for maintaining a professional appearance and preventing defects such as loose or poorly sealed packaging. For products that rely on packaging for both protection and marketing, the uniformity provided by automatic wrapping machines is essential to maintaining a strong brand image.

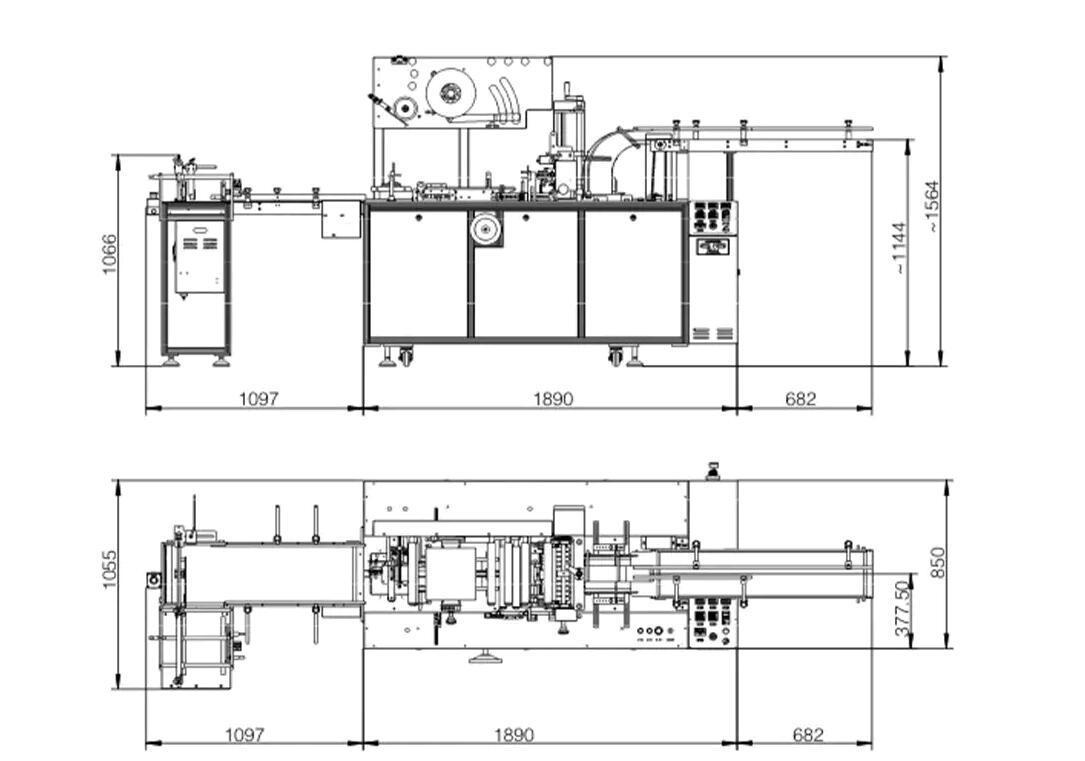

https://www.zjjwjx.cn/product/cellophane-wrapping-machine/jw-260b-fully-automatic-transparent-film-wrapping-machine.html

Packing speed Single box film per minute(20~100)

Package size L(30~200) W(20~120) H(8~50)mm

Input power Three-phase three-wire 220V 50Hz

Design total power 6.75kw

Heat sealing temperature 110-180℃

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness